The Savings

The Energy Savings Could Power 290 Homes!

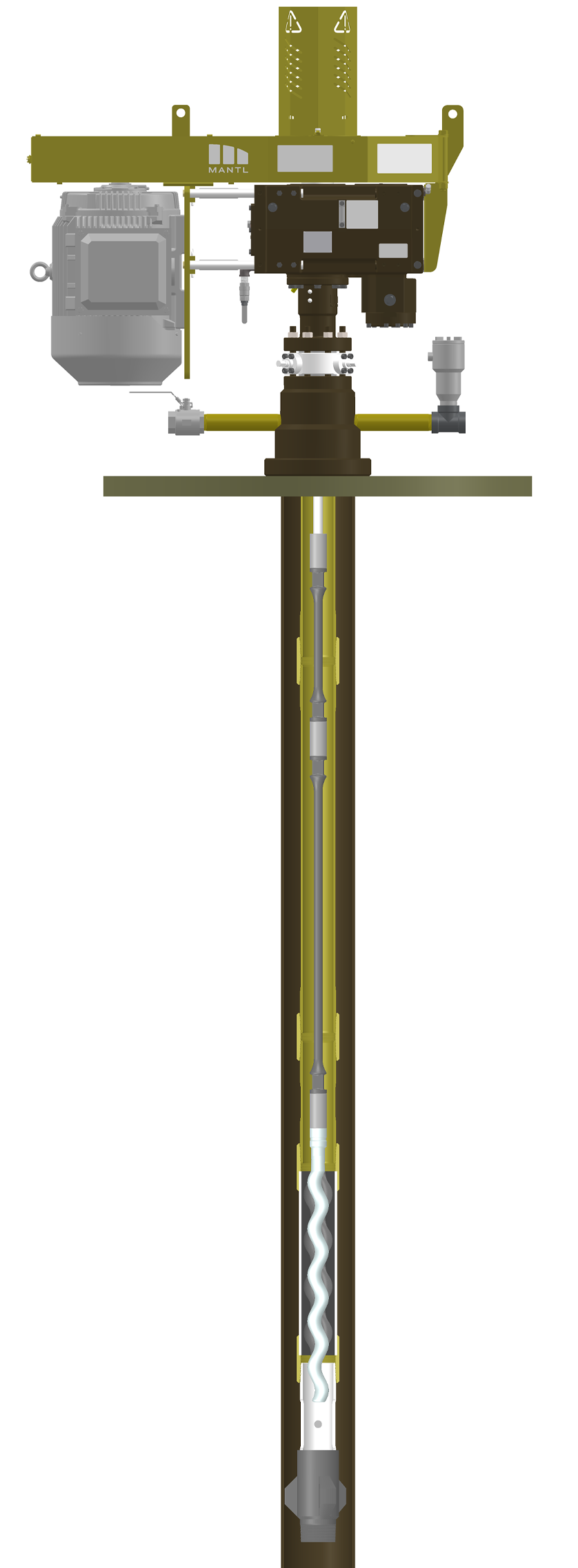

The incredible savings achieved when

converting to Progressing Cavity Pump systems,

comes from both overall power reduction as well

as the reduction in electrical charges based on

demand.

It was noted that even more electrical savings

could be realized by:

- • Utilizing larger diameter tubing

- • Sourcing high efficiency electric motors

- • Using gas separators in high gas production wells

Electricity Demand Savings Are Especially Important

Consumption is the rate at which you consume energy.

Demand charges are based on the highest level of

electricity you demand at over 15 minute intervals

during the billing period. The demand savings are

especially important in reducing production energy

costs. The reduction in demand for these 9 wells is the

equivalent of 290 homes or 32 homes per well!*

*as reported in 2021 energy census for average home consumption

Click Here for PDF